Porous 89/11 bronze filters

AMES offers its customers the ability to manufacture porous bronze filters and components with specific shapes. Each of these special applications requires a specific mould to obtain the desired geometry and pore size. The mould is designed and built entirely in AMES’ dedicated tooling workshop.

| Material | Chemical composition | Other characteristics |

|---|---|---|

| 89/11 sintered bronze | Sn: 10,0 - 11,5%, others: 2% máx., Cu: rest |

Not suitable for contact

with food or sanitary water.

Maximum working temperature: 200°C in an oxidizing atmosphere, 450°C in a reducing atmosphere. Coefficient of linear expansion: ≈18·10-6 K-1 |

| Grade1 | Total porosity(% in volume) | Pore size (μm)2 | Filtering efficiency4(T=98%) (μm) | Permeability5 | ShearStrength (MPa) | Minimumthickness (mm) | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average | Maximum3 | Air | Water | Viscous Ψv (10-12m2)(laminar term) | Inertial Ψi (10-6m)(turbulent term) | ||||||||||||||||||||||||||||||||||||||

| B12 | 30 | 9 | 22 | 3 | 4 | 2.1 | 1 | 180 | 1 | ||||||||||||||||||||||||||||||||||

| B24 | 35 | 22 | 43 | 9 | 10 | 11 | 4 | 140 | 1 | ||||||||||||||||||||||||||||||||||

| B40 | 36 | 40 | 113 | 25 | 28 | 37 | 5 | 130 | 1.5 | ||||||||||||||||||||||||||||||||||

| B60 | 38 | 64 | 127 | 35 | 39 | 70 | 7 | 120 | 1.5 | ||||||||||||||||||||||||||||||||||

| B70 | 39 | 68 | 190 | 38 | 42 | 100 | 8 | 105 | 1.5 | ||||||||||||||||||||||||||||||||||

| B85 | 40 | 82 | 240 | 55 | 65 | 110 | 11 | 95 | 2 | ||||||||||||||||||||||||||||||||||

| B110 | 42 | 101 | 330 | 88 | 98 | 250 | 12 | 70 | 2 | ||||||||||||||||||||||||||||||||||

| B130 | 42 | 128 | 420 | 104 | 115 | 350 | 14 | 65 | 2.5 | ||||||||||||||||||||||||||||||||||

| B150 | 44 | 149 | 450 | 120 | 133 | 400 | 17 | 60 | 2.5 | ||||||||||||||||||||||||||||||||||

- Intermediate grades can be manufactured on demand.

- Measured with a porometer. Pore size, filtering efficiency and permeability scatter: ±25%.

- Equivalent to the bubble point, determined in-out according to the ISO 4003:1977 standard at a continuous flow of 30 ml/min.

- Simulated by a single pass at 0.1 m/s with a 3-mm-thick sample. The wall thickness of the filter strongly influences the filtering efficiency: for more information consult our Technical Department at www.amespore.com.

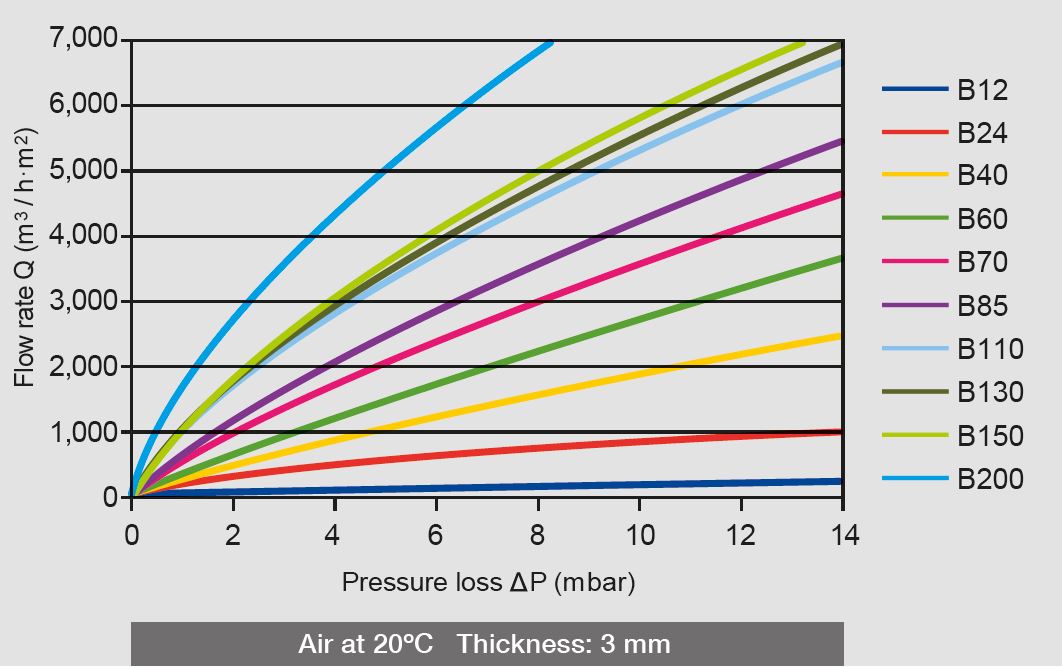

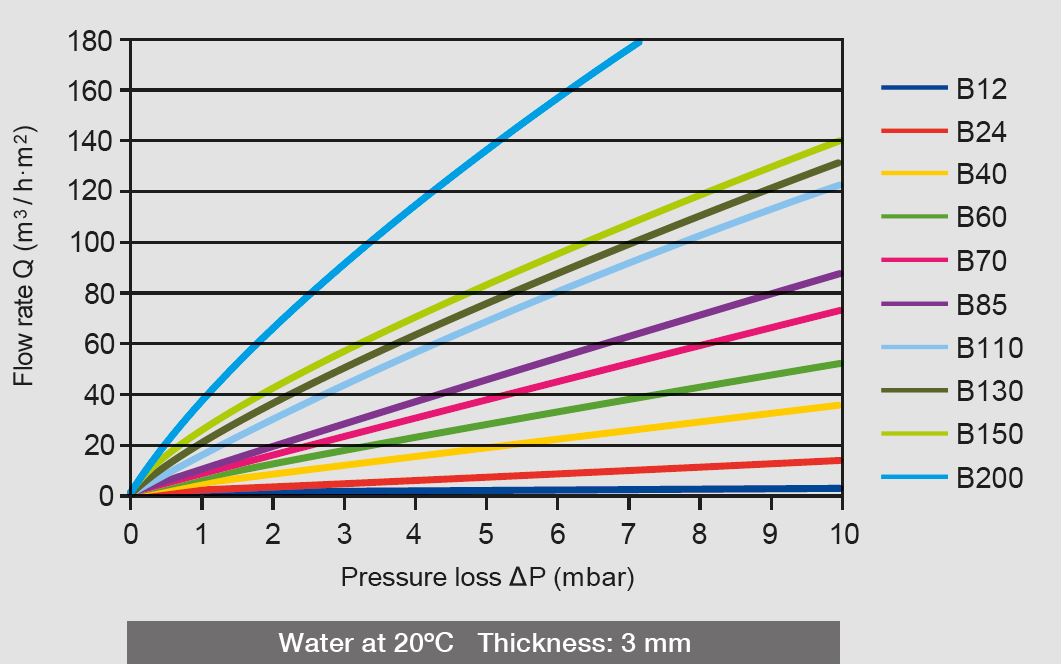

- Measured in air with a 3-mm-thick sample according to the ISO 4022:2018 standard under the following conditions: pressure slope 250 s/bar, maximum pressure difference 1.5 bar, maximum flow 3.3 l/s. Permeability in water is significantly lower than in air: for more information consult our Technical Department at www.amespore.com.

Would you need any information about bronze filters?

AMES can create specific solutions of shapes, materials and performance in which the porosity of the sintered product is tailored to the applications..

Please, contact us and we will answer you as soon as possible.

Thank you!